Selection of the definitive adhesive or adhesives for tests in the xp-Lab

Milestone 1

Phase 1

Laboratory

Phase 1

Laboratory

First, you tell us your requirements, the specifications that must characterize the final product. With the information you give us and your substrate samples, we will select and test suitable components. How does the adhesive behave, does it show the desired adhesive properties? Based on the knowledge gained in this way, our development department will further improve the adhesive or design a new product with which further trial runs and, in particular, laboratory-scale tests can be carried out.

Phase 1 details

Step 1

Formulate requirements to R&D and send customer's substrate sample to laboratory

Step 2

Develop one or more adhesive variants for specific application

Step 3

Coating of selected adhesives on substrate samples in lab

Step 4

Lab tests if and how requirements are met

Step 5

Sample and lab report sent to customer for evaluation of properties

Step 6

Feedback from customer (possible reformulation of adhesive)

Step 7

Decision which adhesive (2 or 3 can be selected as well) will be used for coating tests in xp-Lab

Milestone 1

Selection of the definitive adhesive or adhesives for tests in the xp-Lab

Milestone 2

Customer decision for the definitive adhesive

Phase 2

xp-Lab

Phase 2

xp-Lab

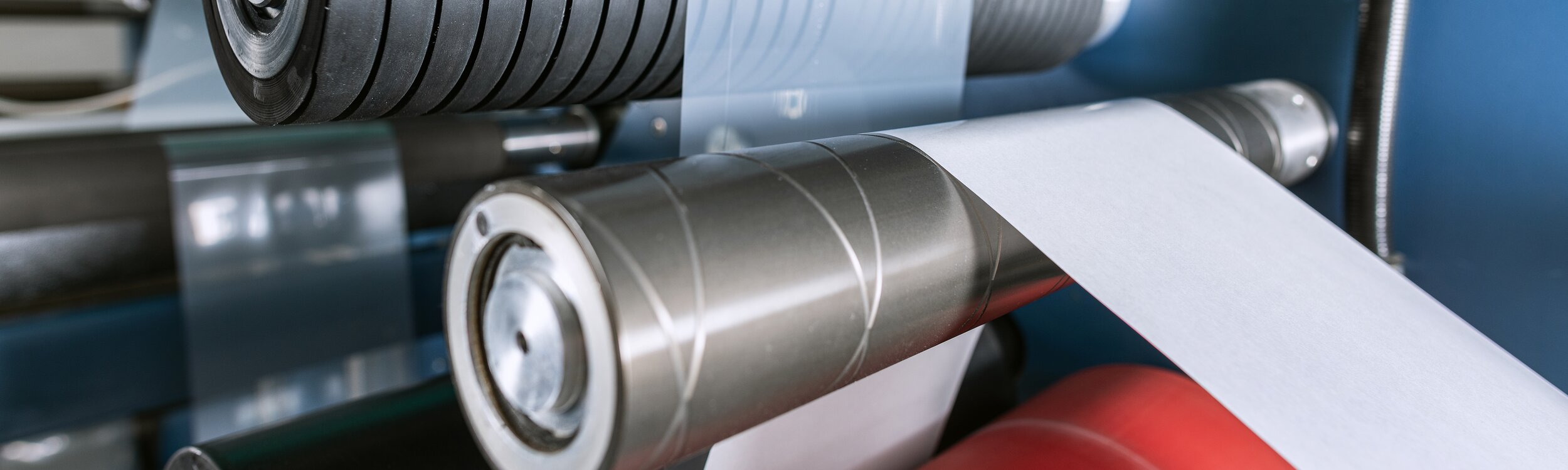

If the samples from the lab are good, but no test slots are available on your production line or test runs cannot be carried out on your premises for other reasons, our test facility comes into play. For this phase, we need sufficient substrates from your side to produce a small series. The artimelt xp-Lab, a high-tech pilot plant from Nordson, represents a unique test platform and enables test settings that are precisely tailored to the objectives of your application.

After the preliminary tests and validation of the lab results, we run a small series as a production run. You then assemble the final product with the coated substrates supplied by artimelt, and finally test whether the assembled products meet the required properties.

Phase 2 details

Step 8

Delivery of customer substrate in larger quantity (see table for dimensions)

Step 9

Production of artimelt adhesive on laboratory or pilot scale

Step 10

Pre-testing and validation of lab results

Step 11

Coating of a small series on xp-Lab pilot plant

Step 12

Packaging of the coatings from the xp-Lab at the customer's site

Step 13

Tests whether finished products function as desired (at customer's site)

Step 14

Decision for the definitive adhesive

Milestone 2

Customer decision for the definitive adhesive

Milestone 3

Start of production of the adhesive and packaging at the customer's site

Phase 3

Upscaling

Phase 3

Upscaling

We manufacture the newly developed adhesive in the desired quantity and ship it to you. Upscaling also includes on-site assistance and consultation to achieve ideal coating results.

Phase 3 details

Step 15

Production and delivery of the defined adhesive in the desired quantity

Step 16

Scale-up support and advice on the optimum coating at the customer's site

Step 17

Start of production series 1 at the customer

Milestone 3

Start of production of the adhesive and packaging at the customer's site