We use cookies to provide you with an optimal user experience. Some cookies are necessary for the operation of the site, others are used for statistical purposes, comfort settings, or to display personalized content. You can decide for yourself which cookies you want to allow. Please note that due to your settings, not all functionalities of the site may be available. For more information, please see our Privacy Policy and Cookie Policy.

Details

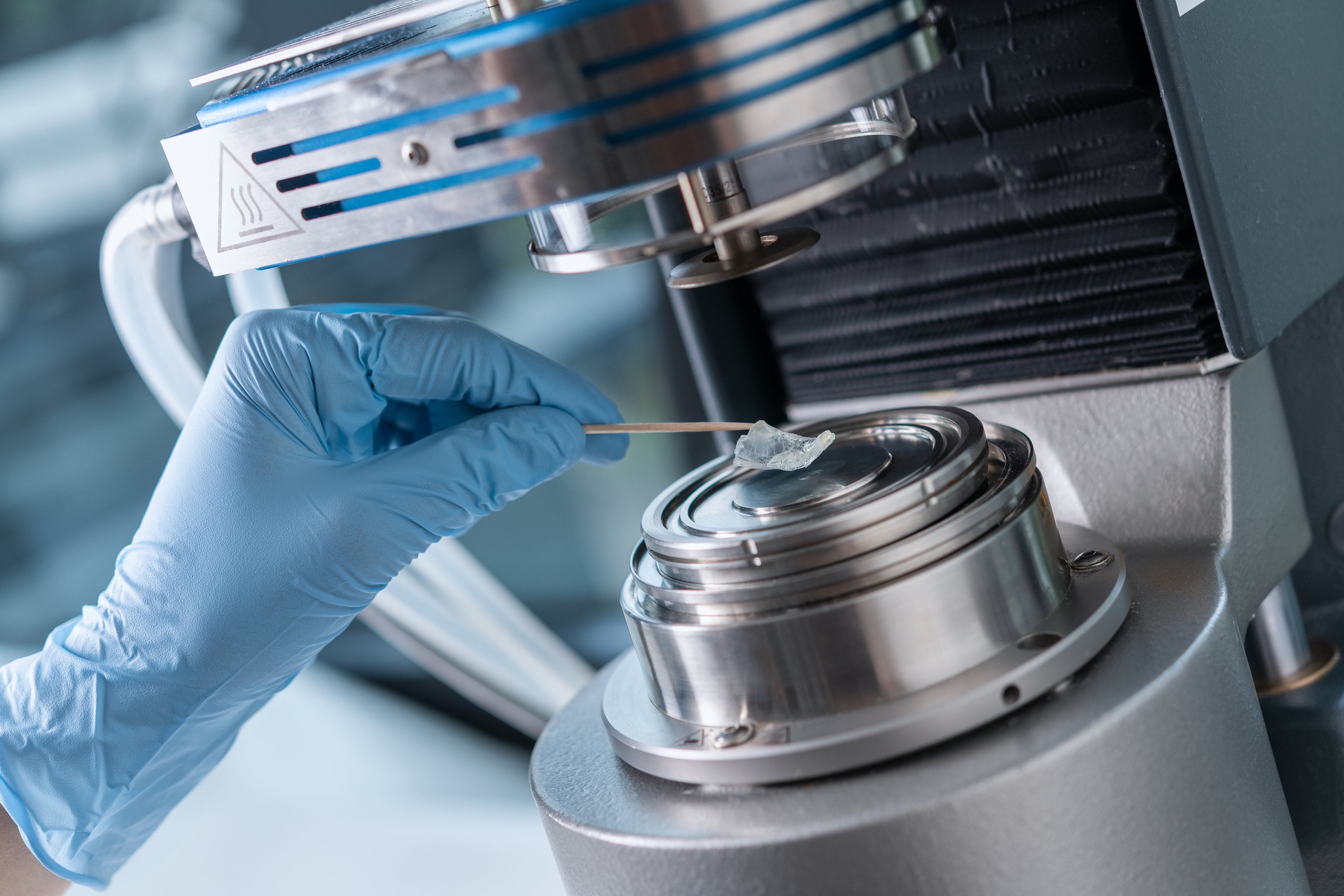

Hot melt Technologies

Hot melt technologies from artimelt

As a proven hot melt specialist, artimelt offers the highest level of expertise in the relevant technologies for the hot melt adhesives sector. Hot melt adhesives have many benefits over solvent-based and dispersion adhesives. As an artimelt customer, our expert knowledge is there for you.

Certified production

The quality of all raw materials is tested immediately after delivery. The raw materials are mixed for several hours at around 266 to 374°F (130 to 190°C) in the production process. Thanks to discontinuous batch production, artimelt is very flexible. Both larger and smaller quantities, including non-industrial sample quantities, can be produced. After the mixing process, all hot melts are tested for viscosity, melting point and other properties. artimelt has over 40 years’ production experience. The company is certified to ISO 9001 and ISO 14001 as well as (EN) ISO 13485 for the development and production of hot melt adhesives for use in the medical device industry.

Processing

Hot melt adhesives produced by artimelt are processed by the customers themselves. The coating is applied via wide slot nozzles, curtain coaters, rollers, bead or spray systems. The adhesive is then applied as a melt to the carrier material at temperatures from approx. 248 to 356°F (120 to 180°C). Hot melt adhesives from artimelt are available in siliconized drums, siliconized boxes and packfree. Our consultation service is also available for advice on any coating issue.

Benefits of hot melt

- Hot melt adhesives from artimelt are a 100% system.

- Hot melt adhesives are produced with comparatively low energy consumption as hot melt adhesives do not need to be dried. All artimelt hot melt adhesives are solvent-free which means, for example, there is no need to invest in the relevant substance recovery systems.

- Thanks to the range of raw materials, artimelt hot melt adhesives offer a wide adhesion spectrum with high water and moisture resistance. Hot melt products are soon ready for further handling, while unused material remains available for processing.

- Investment costs for application equipment are comparatively low. Hot melt adhesives allow pre-coating using a wide range of methods, from extremely thin layers to high application weights

ARTIMELT TECHNOLOGIES

The classic options

The classic hot melt processes produce laminating and sealing adhesives (so-called non-PSA) as well as pressure-sensitive adhesives (PSA), which include UV-curable adhesives. The latter develop their final characteristics only when irradiated with UVC light.

NEW TECHNOLOGIES

Bio-based, colored, indicative

New technologies – bio-based, colored, color-changing

For artimelt, bio-based adhesives are the future. Sustainability is part of artimelt's DNA and the proportion of renewable raw materials is being increased constantly. Equally innovative are the colored, the color-changing and hazard-indicating hot melt adhesives which are suitable for various safety applications and product labeling.

OUR SPECIALITY

Breathable, antimicrobial and sterile

artimelt has been an active partner in the medical sector for many years, specializing in breathable, antimicrobial and sterile adhesives, as well as low-peel adhesives for sensitive skin and water-absorbent products for wound dressings. And we can add color in these application areas as required.

Looking for a specific hot melt solution?

artimelt has the answer.

Are you looking for a specific hot melt solution? artimelt has the answer.

We can develop a solution customized to your specific requirements. Send us the key data and most important features of the product you want, and we'll get back to you.

FAQ

Various raw materials are mixed together to create hot melt adhesives. This produces a free-flowing, homogeneous mixture – the hot melt adhesive.

Hot melt adhesives can be used in many different applications, such as:

- Permanent or removable adhesives for labels, adhesive tapes and security applications on many different substrates

- Lamination of decorative materials (textiles, non-wovens) on wood, metal, plastic or composite carriers

- Reclosable packaging

- Highly transparent "clear-on-clear" labels

- Adhesives for direct contact with food

- Textile laminates for construction applications

- Self-adhesive medical products for direct contact with skin

- And many more

We would be happy to develop a customized hot melt solution to meet your specific requirements.