We use cookies to provide you with an optimal user experience. Some cookies are necessary for the operation of the site, others are used for statistical purposes, comfort settings, or to display personalized content. You can decide for yourself which cookies you want to allow. Please note that due to your settings, not all functionalities of the site may be available. For more information, please see our Privacy Policy and Cookie Policy.

Details

Security

Security

artimelt has more than 20 years’ experience developing hot melts for security applications and, today, is a premium partner of globally active security bag manufacturers for cash and valuables transport and of high-quality envelope producers – of course always in compliance with the required confidentiality.

artimelt hot melts are precisely tailored to specific customer needs. This has resulted in a broad product portfolio of adhesives for security applications.

In addition to security bags for transporting valuables, other areas of application include closures for evidence bags or duty-free store bags. Here, tamper-proofing as well as its evidence are top priorities in combination with the bag materials and printing inks used. Hot melt products from artimelt can also be used for RFID labels, as well as for the production of passports. artimelt adhesives offer good adhesion on VOID prints and security pouches.

With the implementation of the Pharmaceutical Directive 2011/62/EU on protection against counterfeiting of pharmaceutical products, the security concept is becoming increasingly important. Artimelt has suitable hot melt solutions for this as well.

Color Recognition

Thanks to colored adhesives, labels, for example, can be recognized by a machine. This makes it possible to check whether all labels have adhesive or, in the case of transparent labels, whether a label has been applied to each container. The color can be freely selected. This also applies to other applications such as adhesive tapes or closures. A fluorescent adhesive detectable by UV light can also be applied to indicate whether or not adhesive is present.

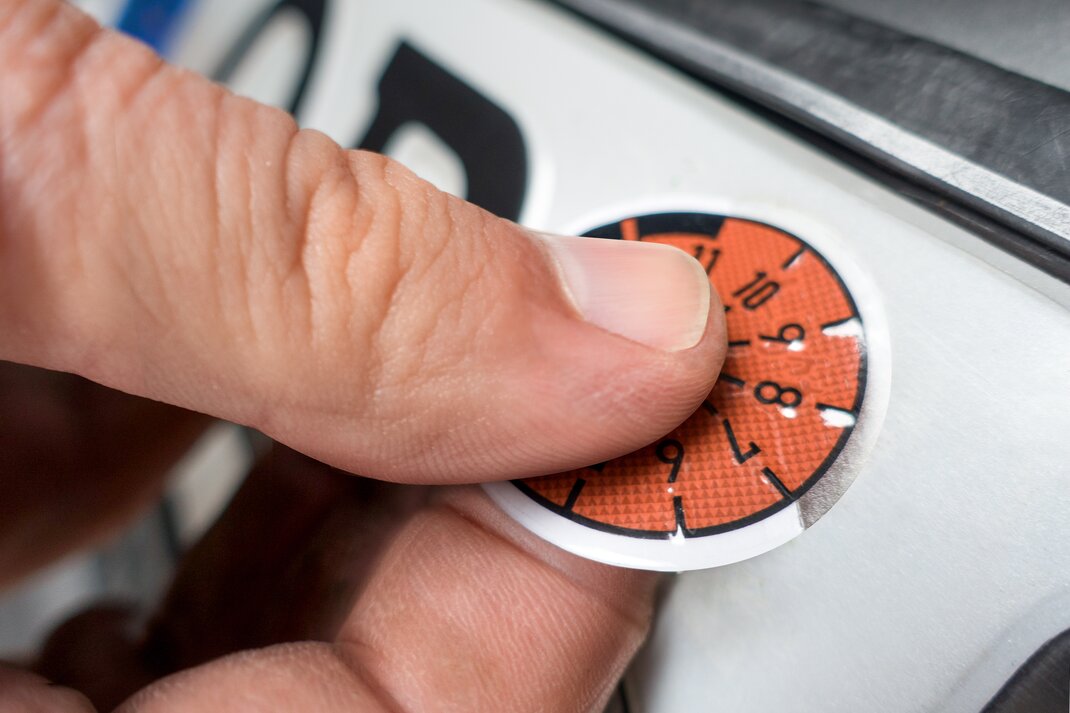

Tamper Indicator

Labels and tapes with hot melt adhesives can be used to detect tampering on, for example, bags with a closure as used by couriers, or for seeds or doping samples, for coin bags or document wallets:

- The packaging material is altered and twisting or even tearing is evident due to the high adhesive force of the adhesive

- The printing ink of so-called void prints is transferred during an opening attempt and a picture or lettering becomes visible; this indicates, for example, that a warranty has expired due to a broken seal

- Thermal ink (printing ink) is used to indicate excessive temperature, for example, when an attempt is made to melt or soften the adhesive; artimelt can develop solutions here that do not impair this property

- Thermal indication of cold, for example when trying to make the adhesive brittle by using a coolant spray; artimelt’s adhesive solution changes color permanently in this case

The above properties can be combined to further increase tamper resistance.

Extra strong adhesion

Particularly strong adhesion is required in applications such as the following:

- Identification tapes

- Access control tapes

- Customs and tax stamps

- Adhesion to difficult surfaces

- Sealing labels for pharmaceutical packaging

Security as a system

One important aspect is that the adhesive is usually only part of the solution. All the components used in a security solution must be perfectly coordinated. In practical terms, security is always a system concept which extends from simple sealing, through different security levels to, ideally, a completely tamper-proof product. To make this possible, different combinations of adhesives, materials and printing inks are used. Hot melt adhesives from artimelt can also be used to provide authenticity protection.